Uncategorized

Up Next…

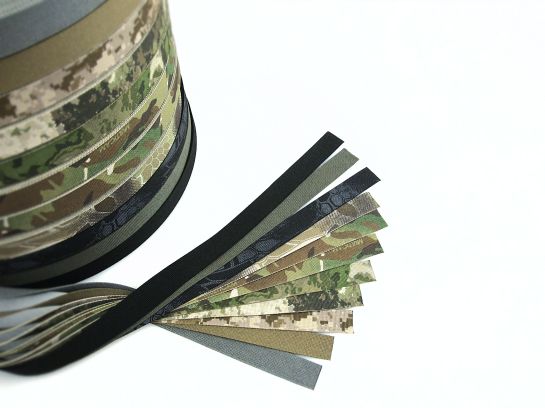

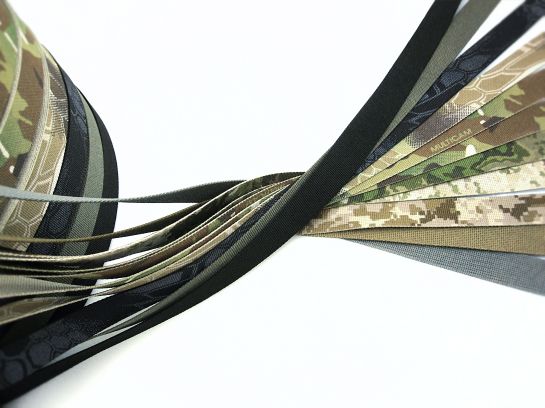

Texcel Webbing In Patterns, Custom Cuts.

Good gear starts with quality components. That’s why Down Range Gear is invested in manufacturers like ITW Nexus, Texcel, Duro, Velcro and National Molding. Having access to these same, military specification materials can also be empowering for customers. That’s win-win and it’s just good business.

Making the parts and materials used in gear production available to customers has to do with a certain infantryman’s need to fix and improve field gear and a business’s imperative to form relationships with key suppliers. For the business the best pricing comes from volume orders. The only items stocked have been those required for gear production. Once in inventory, these same materials could be made available to customers.

In addition to solutions based design, Down Range Gear sees itself as an enabler and today the sale of parts and materials is integral to Down Range Gear’s value proposition. Customers count on no-nonsense pricing, highly detailed, original product photography and concise descriptions to make informed buying decisions.

Now customer interest is becoming a driver to expand inventory.

One such item is Texcel Industries solution dyed, military specification webbing. Texcel solution dyed “textured yarn” sets the bar in the category for tactical applications with accurate colors, a wide selection, consistent tolerances, good weave quality, availability across a spectrum of widths and patterns.

Down Range Gear has added to its inventory with an updated selection of two sided print patterns which now include:

Kryptek Typhon

Kryptek Highlander

Crye Precision Multicam

Desert Digital

A-TACS AU

A-TACS FG

Down Range Gear is also testing a new custom cutting service to complement webbing orders at no additional cost. Customers will be able to order webbing and then request specific cuts. This will give customers with projects ready to use pieces, precision cut and heat sealed to the same professional standards as production gear.

Heat sealing with a hot knife is the preferred way to cut and finish webbing ends. It creates a clean, flat, even end that is durable and protects against fraying. It should be the first step in any project involving nylon materials.

The following conditions apply:

- Contact with Down Range Gear via email with instructions (downrangegear@gmail.com) immediately after the order has been placed. No customization will be accepted after the order has been packaged.

- Some requests will incur delays.

- Measurements must be clearly communicated in inches.

- Availability of the service is limited to what is feasible at the time of the request and Down Range Gear reserves the right to suspend the service as necessary.

- Once cut to specification, all webbing sales are final.

- No other services (marking or sewing) are offered in conjuction with cutting.

- Customers must be available to clarify instructions as necessary to complete the order. If communication is not timely Down Range Gear reserves the right to ship the order as is.

The newly stocked patterns come with the caveat that they are not extended into the existing product line. In other words, the new patterns will not be a standard option in existing designs.

It is simply not feasible to stock ten different colors and patterns for every product and variation. Many of the patterns will work well with companion solid colors. Exceptions can be made on a case by case basis dependent on need and application. Interested parties should enquire directly via email.

Reconsidering The Cummerbund For Plate Carriers

Since first published to Down Range Gear’s Tumblr, there has been a steady flow of requests to retrofit Crye Precision’s Skeletal cummerbund with First Spear’s Tubes hardware. Users want the best of both worlds.

These jobs are challenging and expensive, but fun, breaking the monotony of production routine. Customers who buy Crye Precision and First Spear and take them into the field are users we want to support.

Because the question is asked often, the way this works is that the customer must first acquire both the Skeletal cummerbund and the Tubes hardware, then ship them to Down Range Gear for the retrofit. If you are price sensitive, this game is not for you.

As a small, custom oriented shop, Down Range Gear constantly iterates and can implement design changes as quickly as the need is identified. The original Tubes/Skeletal cummerbund retrofit was serviceably constructed with webbing, but as new, non-woven materials became available, an improved, single piece end cap was fabricated, allowing for a clean, simplified solution.

It would seem a lot of users want the stripped down minimalism of the Crye Precision cummerbund with the ease of use the First Spear hardware affords. Providing the bridge between the two puts Down Range Gear in good company while customers‘ trust speaks for itself.

Now, let’s drill deeper with the question that isn’t being asked.

How often do we challenge the notion that we even need to pair a cummerbund with a plate carrier in the first place? Yes, a plate carrier requires a way to join the front and back, securing the sides. If you have to carry supplemental armor or need room to support additional equipment, you already have your answer: you need it. But what about the users who run plate carriers with no side armor and no pouches off the plates?

Nearly all plate carriers ship with cummerbunds, and that’s how they’re fielded by default. How many challenge the assumption that they need one and, for that matter, what would it be like to run an armor carrier without?

We tend to stick with what we know. Whether or not it’s actually better is an individual decision the user has to make. Weigh your need, decide accordingly. But there are other ways to secure the sides of a plate carrier. The first step to making an informed decision is to ask the question.

The following is directed at the user who does not use the additional real estate MOLLE surfaced cummerbunds afford and who does not require additional soft armor or side plate protection. In other words, it’s not for everybody, but could be very useful for some.

So if not a cummerbund, then what?

Down Range Gear turned from conventional, webbing based straps to the Dynamic Strap System, a high performance alternative relying on a shock cord core sheathed in tubular nylon webbing. It’s flexible, non-abrasive, enables good range of motion and, once elastic tension is set, eliminates the need for repeat adjustment.

The Lateral Strap variant of the Dynamic Strap System was originally designed as a plate carrier side closure. A recent opportunity with a Crye Precision JPC allowed us to revisit that application, pairing it with one of the most respected brands in the industry, and contrasting with the excellent Skeletal cummerbund.

The Dynamic Strap System will retrofit onto nearly any 1” attachment point, including MOLLE webbing and loops sewn to the sides of armor carriers. As such, it requires no permanent alteration. For many customers, this aspect is important. All the hardware is standard ITW Nexus split bar variants. That means they are designed to slot easily onto existing 1” webbing attachment points with no special tools or damage to the base system. If you went out of pocket on your gear, this matters to you.

The Crye Precision JPC was a particularly good candidate for this treatment. Readily available attachment points made DSS Lateral Strap installation easy; onto existing MOLLE webbing at the back and with buckles slotted onto webbing loops at the front edge of the plate carrier, like they were made for each other.

The DSS Lateral Straps keep everything tight without a hard limit or constriction on range of motion. It’s great for mobility. Kitting up is simplified because once elastic tension is set to what is effective and comfortable, it’s locked in and left alone, no cinch down required.

This solution was not for everybody. Both the cummerbund and strap system have trade offs but it never hurts to take a critical look at how your gear is configured, to reconsider and revise accordingly. No one else can make that decision for you but we can offer one more option worthy of consideration.

We're only scratching the surface with this concept and customers should expect this application to be taken further in the near future.

Thank You, Jerking The Trigger, Soldier Systems Daily, Tactical Life

We don’t exist in a vacuum. Your next great tactical gear idea doesn’t go very far if nobody knows about it.

We don’t exist in a vacuum. Your next great tactical gear idea doesn’t go very far if nobody knows about it.

This week Down Range Gear had a welcome bump from Jerking The Trigger, Soldier Systems Daily and Tactical Life.

Thank you.

“Kick-start” This.

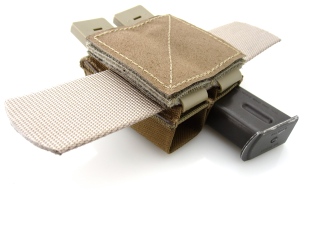

The Regulation Tactical Reflex Mag Pouch Mk2.

The CDH-Tac Finland Lowirde Panel.

The convergence of these two pieces of gear makes for interesting belt carry options with unique capabilities. We have a rare opportunity to offer this gear combination in a package deal at a meaningful discount to customers.

First, the gear.

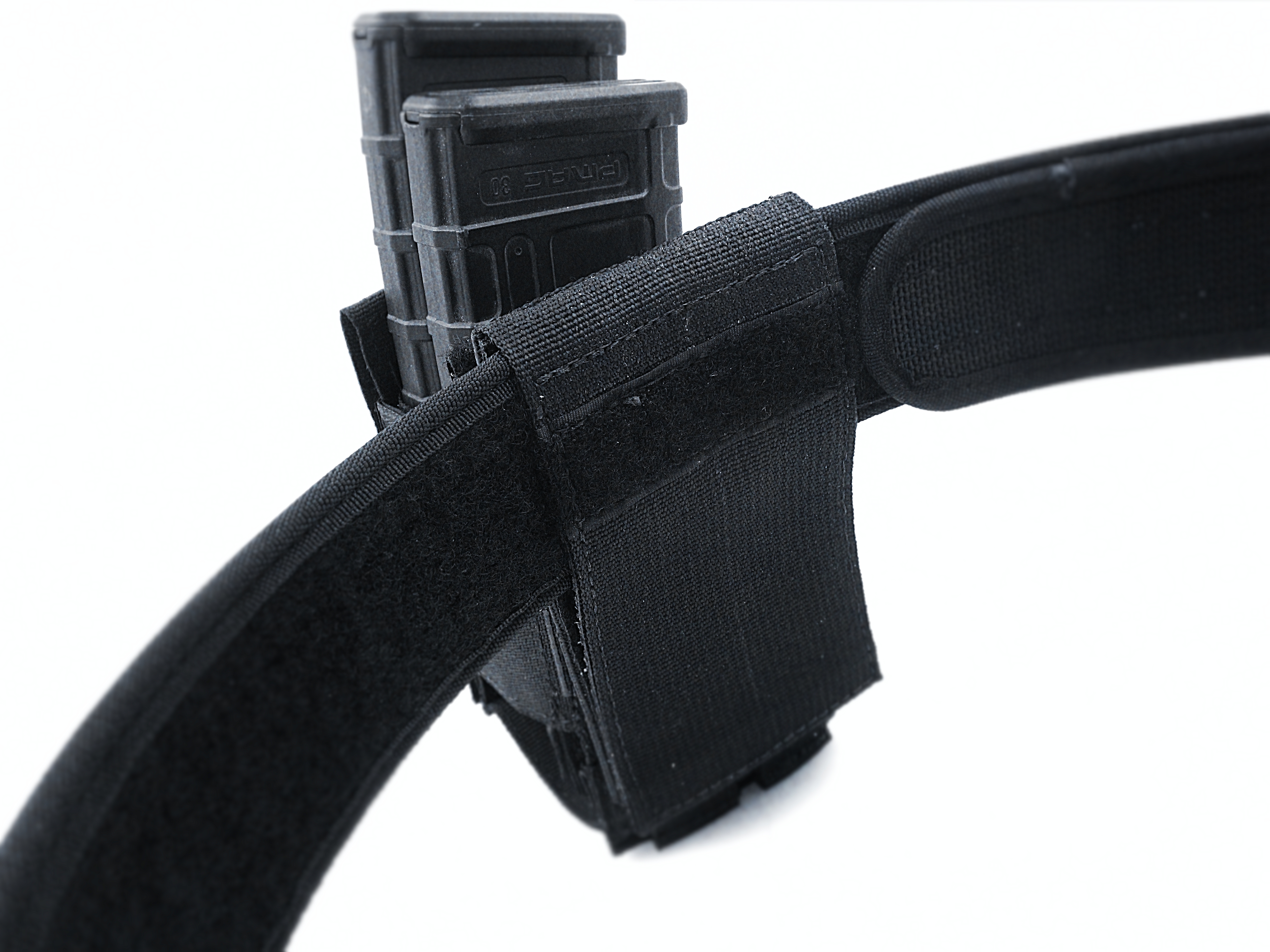

Are you familiar with Regulation Tactical's Reflex Mag Pouch? It's an idea ahead of it's time on a short list of really innovative products in this category. The defining feature is a mechanism that keeps the magazine under constant tension for excellent retention in a fast, open top structure. It gets more interesting with a design that is adjustable from single to double stack configurations. With two magazines inserted, the outer magazine protrudes slightly higher than the inner for easier access and, when drawn, the second magazine is loaded to the "ready" position. Having a double stack which is also an effective speed reload pouch is really useful. If you are a practitioner of magazine management and rotation (and if you carry a weapon for a living, you should be) this pouch directly supports that TTP, allowing users to prioritize sources of ammunition. All this on a MOLLE compatible system with a removable flap.

First, the gear.

Are you familiar with Regulation Tactical's Reflex Mag Pouch? It's an idea ahead of it's time on a short list of really innovative products in this category. The defining feature is a mechanism that keeps the magazine under constant tension for excellent retention in a fast, open top structure. It gets more interesting with a design that is adjustable from single to double stack configurations. With two magazines inserted, the outer magazine protrudes slightly higher than the inner for easier access and, when drawn, the second magazine is loaded to the "ready" position. Having a double stack which is also an effective speed reload pouch is really useful. If you are a practitioner of magazine management and rotation (and if you carry a weapon for a living, you should be) this pouch directly supports that TTP, allowing users to prioritize sources of ammunition. All this on a MOLLE compatible system with a removable flap.

http://www.regulationtactical.com/collections/all

http://www.regulationtactical.com/collections/all

Then we add real duty belt carry capability.

By now the CDH-Tac Finland Lowride Panel is a known quantity. It allows something most shooters have probably thought about doing: putting a state of the art MOLLE compatible pouch on a belt. Like Regulation Tactical, the designer built more into the design. The solid 2 column, 5 row PALS grid starts at belt height and then drops below it, clearing armor and other equipment for better access. As the Regulation Tactical Reflex Pouch demonstrates, MOLLE compatible pouches are, rightly, where all the innovation is. If you want that versatility on a belt, you need a capable adapter to make it work. The Lowride Panel keeps it simple with a fold over, internally reinforced design that secures over compatible belts with hook and loop. Belt width is not an issue. Hook and loop surfaces on both sides lock the Lowride Panel into place. This solution is practically tailor made for law enforcement duty belt applications.

https://www.facebook.com/pages/Cdh-Tac-Finland/141110645925106

Then we add real duty belt carry capability.

By now the CDH-Tac Finland Lowride Panel is a known quantity. It allows something most shooters have probably thought about doing: putting a state of the art MOLLE compatible pouch on a belt. Like Regulation Tactical, the designer built more into the design. The solid 2 column, 5 row PALS grid starts at belt height and then drops below it, clearing armor and other equipment for better access. As the Regulation Tactical Reflex Pouch demonstrates, MOLLE compatible pouches are, rightly, where all the innovation is. If you want that versatility on a belt, you need a capable adapter to make it work. The Lowride Panel keeps it simple with a fold over, internally reinforced design that secures over compatible belts with hook and loop. Belt width is not an issue. Hook and loop surfaces on both sides lock the Lowride Panel into place. This solution is practically tailor made for law enforcement duty belt applications.

https://www.facebook.com/pages/Cdh-Tac-Finland/141110645925106

Reflex Magazine Pouch + Lowride Panel = win.

Putting these two innovative products together to offer an integrated belt carry system was the obvious thing to do. Working in conjunction with Regulation Tactical and CDH-Tac Finland, we have a compelling, limited duration packaged deal.

The numbers:

CDH-Tac Finland Lowride Panel MSRP $19.95

Regulation Tactical Reflex Mag Pouch Mk2 MSRP $35.00 CORRECTION: $30

Total shipping (if purchased separately) $15(+) CORRECTION, SEE COMMENTS BELOW

Total: $69.95 CORRECTION, SEE COMMENTS BELOW

Reflex Magazine Pouch + Lowride Panel = win.

Putting these two innovative products together to offer an integrated belt carry system was the obvious thing to do. Working in conjunction with Regulation Tactical and CDH-Tac Finland, we have a compelling, limited duration packaged deal.

The numbers:

CDH-Tac Finland Lowride Panel MSRP $19.95

Regulation Tactical Reflex Mag Pouch Mk2 MSRP $35.00 CORRECTION: $30

Total shipping (if purchased separately) $15(+) CORRECTION, SEE COMMENTS BELOW

Total: $69.95 CORRECTION, SEE COMMENTS BELOW

We can sell the same package for $45.00, shipped.

We are looking for a minimum 35 pledged orders to make this happen. Deadline for sign up is December 15. There is no up front financial commitment, only the announcement of a serious intent to purchase. If we reach or exceed the 35 piece minimum, it's on. If there is insufficient interest, the deal falls through. • Customer's choice of (1) CDH-Tac Lowride Panel in Black or Coyote Brown. • Customer's choice of (1) Regulation Tactical Reflex Mag Pouch Mk2: Black, Coyote Brown, Crye Multicam, Ranger Green. • Customers are welcome to buy as many as they would like with no upper limit. • Free shipping. How it works:

The offer expires on December 15 and is only valid if the required minimum is reached. Orders will be electronically billed via email and ship upon reaching the 35 piece threshold. If the minimums are not met, we will post the expiration via this blog post.

Interested parties should respond using the "reply" feature to this blog post and email DownRangeGear@gmail.com, subject line: "Reflex Pouch/ Lowride Panel Offer."

How it works:

The offer expires on December 15 and is only valid if the required minimum is reached. Orders will be electronically billed via email and ship upon reaching the 35 piece threshold. If the minimums are not met, we will post the expiration via this blog post.

Interested parties should respond using the "reply" feature to this blog post and email DownRangeGear@gmail.com, subject line: "Reflex Pouch/ Lowride Panel Offer."

Lastly, for those interested, additional product images are being posted to the Down Range Gear Tumblr all week long.

Lastly, for those interested, additional product images are being posted to the Down Range Gear Tumblr all week long.

That Time Of Year

We’re clearing some inventory on Down Range Gear’s Limited Sales page with free shipping and reduced rates for designs that are not regular production items. Customers are invited to have a look and shoot us an email regarding inquiries. Supplies are limited to stock on hand. This offer expires on December 15.

The Horizontal Belt Adapter

The Horizontal Belt Adapter was created to provide a niche capability so if you’re looking at it, wondering why anybody would want one, you are probably not the intended user. There won’t be many, but the few that have the need will get it right away.

http://downrangegear.net/Down_Range_Gear_Horizontal_Belt_Adapter.html

The Horizontal Belt Adapter is designed to support any two column, MOLLE compatible pouch on a belt in a horizontal orientation. Three 1″ webbing components act as rows in a PALS grid and are sewn into columns onto which a pouch can be attached.

Lengths of 1″ webbing are folded over and sewn to form two loops. The upper loop is sized for specific belt widths from 1-1/2″ to 2″ and backed with a small hook (Velcro) square to lock into compatible belts. The lower loop is built to 1-1/2″ PALS specification. A belt provides the side oriented mounting platform for the loops and attached pouch. Proper alignment with the pouch is achieved as the pouch is woven in and locked down.

The applications for this are limited to specific use cases but it was designed to meet a need few other pieces of gear address.

The origin dates back to a small combat outpost in western Iraq where a weapon and source of ammunition were required at all times though PPE and a full combat load were not unless outside the wire or under fire. A 30rd rifle magazine can be awkward size and shape on a trouser belt when carried all day every day in a variety of settings. Standing up, no problem; sitting down, more uncomfortable. Given the magazine’s size and shape, small of the back was a good place to keep it out of the way and relatively comfortable but accessible. The added benefit was that when kitted up and outside the wire, it tucked neatly under the bottom edge of armor and could serve as a last ditch, emergency source of ammunition.

Need and application will vary from user to user. Whether or not this is the right solution will depend as much on the pouch as the platform and adapter. If you have the need, this is one way to do it.

http://downrangegear.net/Down_Range_Gear_Horizontal_Belt_Adapter.html

Readers are welcome to post comments. The link above takes you to the e-commerce site. Direct email traffic to downrangegear@gmail.com

The PALS Belt Platform

New ways of seeing things lead to new ideas. New ideas make new designs possible. The re-release of the PALS Belt Platform is the culmination of a lot of work and one of those new ideas. It moves the concept into new territory with interesting possibilities.

http://downrangegear.net/Down_Range_Gear_PALS_Belt_Platform_For_1-1_2%22_%26_1-3_4%22.html

http://downrangegear.net/Down_Range_Gear_PALS_Belt_Platform_For_2%22.html

The PALS Belt Platform is designed to adapt any MOLLE compatible pouch for use on a belt by means of a compact, 2 x 2 grid that fully supports the attachment system.

Running pouches with MOLLE compatible attachment systems on a belt has always been problematic. Before it was even an option, separate, dedicated pouches had to be designed specifically for belt use, complicating logistics and adding expense. That limitation continues to impact selection and availability because the best designs built for modular attachment may not have dedicated belt variants. Clearly the way forward is for users to pick the pouch they want and then use an adapter to extend it’s capability.

That’s the reason the PALS Belt Platform exists: modular pouch integration with belts.

The PALS Belt Platform forms a 2 x 2 PALS grid that will support a typical rifle magazine pouch or two pistol magazine pouches in tandem. It works by spacing two webbing rows, sewn in PALS columns that, when folded over a belt correctly align into a row-gap-row configuration onto which pouches can be woven. That shape also forms the loop through which the belt is fed.

When it comes to MOLLE compatible attachment systems, security comes from properly weaving the pouch into a PALS grid. That’s how they were meant to and should work. Weaving a pouch into a backing creates multiple points of contact pulling evenly across the surface, locking into the grid. Not doing it the right way is asking for trouble. The PALS Belt Platform is designed to be stable on belts both with and without Velcro liners. An opposing hook and loop surface is built in for contact with the underside of compatible belts. It works well with two tier, inner/outer duty belt sets. For belts without Velcro, removable, non-slip patches can be affixed to both sides to increase friction and minimize shifting.

The PALS Belt Platform is designed to be stable on belts both with and without Velcro liners. An opposing hook and loop surface is built in for contact with the underside of compatible belts. It works well with two tier, inner/outer duty belt sets. For belts without Velcro, removable, non-slip patches can be affixed to both sides to increase friction and minimize shifting.

Using PALS Belt Platform takes more time to describe than set up:

1. Position the PALS Belt Platform behind the belt. Unmask the Velcro or leave the non-slip liner on as appropriate.

2. Fold the top row of webbing over the front of the belt.

3. Pass the MOLLE straps from the pouch through the top row of webbing.

4. Weave the MOLLE straps back into the next full row on the pouch.

5. Weave the MOLLE straps through the bottom row on the PALS Belt Platform. Secure the strap ends at the bottom of the pouch. If the MOLLE webbing on the pouch extends further, it is recommended the straps be passed through them before locking the ends down.

One interesting feature afforded by the PALS Belt Platform is the ability to daisy chain multiple units on a belt to support pouches in tandem. This will be useful for customers who need to support equipment but don’t want to run a full featured battle belt. Customers who want to run multiple units on their belts can take advantage of the six piece sets sold at a discounted rate.

The PALS Belt Platform is sized for common belt widths in 1-1/2″, 1-3/4″, and 2″. Color options will be coyote brown for customers who need a military compatible earth tone and black for agency users.

The PALS Belt Platform has a lot of potential for law enforcement agencies. While department/agency policy may be an obstacle, the PALS Belt Platform removes the constraint of equipment limitations allowing the full range of MOLLE compatible pouches on 2″ duty rigs.

Some of the most innovative and original pouch designs on the market today are built for modular attachment. They can now be run as low profile, dedicated belt pouches. The PALS Belt Platforms joins the MALICE Clip Belt Stabilizer and CDH-Tac’s Lowride Panel in Down Range Gear’s line of adapters.

Some of the most innovative and original pouch designs on the market today are built for modular attachment. They can now be run as low profile, dedicated belt pouches. The PALS Belt Platforms joins the MALICE Clip Belt Stabilizer and CDH-Tac’s Lowride Panel in Down Range Gear’s line of adapters.

http://downrangegear.net/Down_Range_Gear_PALS_Belt_Platform_For_1-1_2%22_%26_1-3_4%22.html

http://downrangegear.net/Down_Range_Gear_PALS_Belt_Platform_For_2%22.html

Readers are welcome to post comments. The link above takes you to the e-commerce site. Direct email traffic to downrangegear@gmail.com

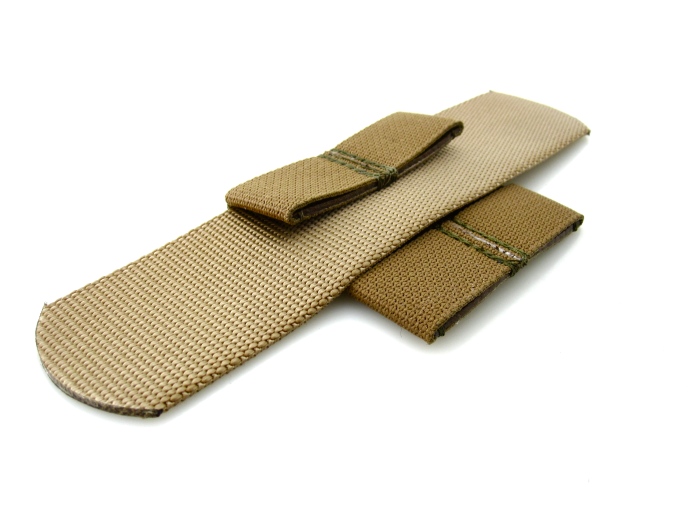

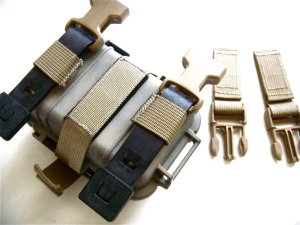

CDH-Tac Lowride Panel

Gear maker CDH-Tac, Finland has an impressive portfolio. This independent designer has consistently put out practical, innovative and well executed designs.

https://www.facebook.com/pages/Cdh-Tac-Finland/141110645925106

Doing good work while maintaining a high level of integrity is what makes this designer stand out because when it comes to making decisions about who you want to work with, those choices reflect and character matters. It was immediately apparent that the Lowride Panel would complement a niche that Down Range Gear has been developing for some time so we were thrilled to have the opportunity to build the design under license. Not only does it fit in with Down Range Gear’s line of belt adapters but also gives us the opportunity to work closely with a great designer.

http://downrangegear.net/Down_Range_Gear_CDH-Tac_Lowride_Panel.html

The Lowride Panel supports MOLLE compatible pouches on a belt with an extended PALS grid that drops below the belt line to clear equipment and improve access to pouches. It’s the sort of solution based design that is common from an end user who has identified the need from practical experience… and then does something about it. A lot of users are going to get the concept as soon as they see it.

By now everybody knows the real advances in pouch design are built almost exclusively for modular attachment systems, not around belt carry. To make those pouches work on a belt and get the benefits of the best in equipment technology requires a way to bridge the gap. The Lowride Panel provides that capability, opening the world of high end modular pouches to belt systems that lack the native ability to support them.

The Lowride Panel uses a fold over design that bends over the top of the belt and secures below it with large, interior hook and loop fields. This makes it particularly effective with Velcro lined belts and compatible with virtually any width. The addition of a small strip of loop (Velcro) material on the back face locks it into inner support belts such as two piece, inner/outer LE nylon duty belt systems.

The Lowride Panel uses a fold over design that bends over the top of the belt and secures below it with large, interior hook and loop fields. This makes it particularly effective with Velcro lined belts and compatible with virtually any width. The addition of a small strip of loop (Velcro) material on the back face locks it into inner support belts such as two piece, inner/outer LE nylon duty belt systems.

The outer face of the Lowride Panel is surfaced with a 2 column, 5 row PALS grid supporting all MOLLE compatible pouch attachments. The 2×5 configuration was designed to accommodate two pistol magazine pouches in tandem or a single rifle magazine pouch. If a wider surface area is required,  multiple panels can be “daisy chained” onto the belt.

multiple panels can be “daisy chained” onto the belt.

The PALS grid is a “solid” design with 5 contiguous rows that allow for 1″ increments of adjustment. Magazine pouches typically require 2 conventionally spaced rows to properly weave in, leaving 2 rows (or 2″) of up or down positioning to find optimal height on the Lowride Panel. For a dedicated duty belt this is enough to drop pouches below armor and clear other equipment.

The Lowride Panel is built on a sturdy 3″ webbing base folded over. Opposing hook and loop (Velcro) liners surface the interior securing the two sides. The outer, 2×5 contiguous PALS grid is sewn with the webbing ends rolled and tucked in at the seam. The PALS grid is backed with an internal HDPE (plastic) semi-rigid support which provides a solid surface for mounting pouches. A strip of loop Velcro runs across the back to lock the panel into compatibly surfaced belts.

The Lowride Panel is currently being produced in coyote brown for users who require a military earth tone and black for agency customers.

Users will find the Lowride Panel equally at home on an LE duty belt dropped clear of other equipment as well as a low profile way to carry pouches below the belt line without a heavy, dedicated MOLLE belt.

This is the first outside design produced under license by Down Range Gear and it would not have been possible without the confidence of CDH-Tac. Under our agreement, profit for every unit sold is paid back to the designer as a royalty. Association with a designer as good as CDH-Tac naturally makes you want to do better work; we’re better for it and the customer ultimately benefits.

http://downrangegear.net/Down_Range_Gear_CDH-Tac_Lowride_Panel.html

Readers are welcome to post comments. The link above takes you to the e-commerce site. Direct email traffic to downrangegear@gmail.com

Reintroducing The MALICE Clip Belt Stabilizer

Because it was one of the earliest Down Range Gear designs, it is fitting that the new MALICE Clip Belt Stabilizer be among the first featured with the relaunch of this blog.

Because it was one of the earliest Down Range Gear designs, it is fitting that the new MALICE Clip Belt Stabilizer be among the first featured with the relaunch of this blog.

http://downrangegear.net/Down_Range_Gear_MALICE_Clip_Belt_Stabilizer.html

The MALICE Clip Belt Stabilizer allows the use of a pouch equipped with the Tactical Tailor MALICE Clip to interface with a belt.

Traditionally, manufacturers have had to build separate versions of each pouch for modular attachment and belt use. With the advent of adapters like the MALICE Clip Belt Stabilizer a user can run the same pouch interchangeably to fill both roles.

Traditionally, manufacturers have had to build separate versions of each pouch for modular attachment and belt use. With the advent of adapters like the MALICE Clip Belt Stabilizer a user can run the same pouch interchangeably to fill both roles.

This capability makes the pouches more versatile, increasing the options for belt gear, simplifying the loadout, and making procurement much easier: don’t worry about compatibility, just buy the pouch you want to run and then find the appropriate adapter. Our job will be to make sure that the search begins and ends with Down Range Gear. For law enforcement and agency users, it opens a whole new world of possibilities for both duty rigs and discreet carry. Now, every pouch is a belt pouch, and not in a superficial, quick fix way.

the search begins and ends with Down Range Gear. For law enforcement and agency users, it opens a whole new world of possibilities for both duty rigs and discreet carry. Now, every pouch is a belt pouch, and not in a superficial, quick fix way.

The MALICE Clip by itself forms a viable belt loop. More than any other modular attachment system, the MALICE Clip is ideally suited because of it’s rigid structure, secure locking system and useful fold over, single piece design.

Taking a closer look: the MALICE Clip slots in behind the pouch webbing, then is bent over the top and folded over. For belt use, rather than weave it into the MOLLE backing, simply securing the end results in a closed, rudimentary belt loop. The problem is that at best it’s a 2″ – 3″ belt loop made of a piece of plastic and not inherently stable.

The Belt Stabilizer doesn’t actually attach the pouch to a belt. It does provide a channel for the MALICE Clip to feed into behind the belt, giving it a friction hold and stability. The MALICE Clip hugs the Belt Stabilizer against the belt. Then when the belt is donned and cinched down, it also pulls the Belt Stabilizer against the wearer’s torso creating a second contact surface to hold the pouch in place. Those two points of friction are important and you won’t see the full benefit of the design until it’s actually being worn.

The original Belt Stabilizer was surfaced on both sides with a high friction, nonslip liner. The LE Variant was designed with hook and loop to interface with Velcro lined belt systems.

For 2013, everything learned from constant design iteration and practical use has culminated in an updated, hybrid design with a removable nonslip liner that peels off to unmask an underlying hook and loop construction. This two layer system gives users the best of both concepts in one package: the friction hold with nonslip material and hook and loop, to take advantage of Velcro liners.

Here’s a walk through of how it works in three simple steps:

Here’s a walk through of how it works in three simple steps:

1. Run the MALICE Clip through a channel in the Belt Stabilizer.

2. Slide the pouch onto the end of the MALICE Clip.

3. Fold the Malice Clip over and insert the end into the tab at the base, locking it to secure the loop.*

*For greater convenience, it might be easier for some users to install the Belt Stabilizer over the belt and not have to thread it on after installation.

The current, default configuration for the Belt Stabilizer is a 2 column design which will support the width of a standard rifle magazine pouch or two pistol magazine pouches mounted in tandem. A 3 column variant will be released later in the year. Customers who require a configuration other than what is provided can “daisy chain” Belt Stabilizers onto a belt to achieve the desired width. Combinations of 2 and 3 column Belt Stabilizers should address most needs. For those problems that can only be solved with an off the shelf solution, custom fabrication is always an option.

The current, default configuration for the Belt Stabilizer is a 2 column design which will support the width of a standard rifle magazine pouch or two pistol magazine pouches mounted in tandem. A 3 column variant will be released later in the year. Customers who require a configuration other than what is provided can “daisy chain” Belt Stabilizers onto a belt to achieve the desired width. Combinations of 2 and 3 column Belt Stabilizers should address most needs. For those problems that can only be solved with an off the shelf solution, custom fabrication is always an option.

http://downrangegear.net/Down_Range_Gear_MALICE_Clip_Belt_Stabilizer.html

Readers are welcome to post comments. The link above takes you to the e-commerce site. Direct email traffic to downrangegear@gmail.com

…Where To Begin?

Back in October 2011, when the last post was made on this blog, Down Range Gear was facing a fundamental small business problem. A lot of unique concepts were shown publicly without the business infrastructure to sell them. Among other things in this business, you live and die by your original, differentiating ideas. If you show your cards and don’t make an effort to play the game, you’re stupid. And the business suffered for it. Hence the year (+) long retrenchment.

Back in October 2011, when the last post was made on this blog, Down Range Gear was facing a fundamental small business problem. A lot of unique concepts were shown publicly without the business infrastructure to sell them. Among other things in this business, you live and die by your original, differentiating ideas. If you show your cards and don’t make an effort to play the game, you’re stupid. And the business suffered for it. Hence the year (+) long retrenchment.

Since this blog went on hiatus, a lot of things have changed. The wider industry of course never stands still. A number of concepts that first showed up on this blog years ago have gone mainstream. Despite the quiet outward appearance, Down Range Gear has maintained a very busy tempo behind the scenes. That’s what the rest of this post is about.

Down Range Gear has a new look, the best example of which is emerging at downrangegear.net, the new, standalone e-commerce site. If you haven’t found it yet, take a few seconds to have a look around. It’s a work in progress but the look and feel is starting to settle and the hard work of developing and listing product is well underway. It will steadily fill out in the weeks and months ahead.

Introducing downrangegear.net

Downrangegear.net was built on basic and dated software which will constrain functionality until it is migrated onto a more sophisticated platform. Despite this handicap, the design is deliberately simple. Functional issues aside, the key idea was to strip the site down to it’s most essential components in order to load quickly and then get out of the customer’s way. That means a clean design with big pictures, an intuitive layout that shows everything up front without the need for elaborate navigation with never more than 2 clicks to make a purchase.

If the site looks empty it’s because of the lack of extraneous content and clutter. Does the customer need to read a copy write notice? There are good legal reasons to have one but what does it have to do with buying gear? Shipping, warranty, contact information and a few links are all tucked in at the bottom and out of the way. You can find them if you need to but you probably didn’t jump on the site to read about that. The things you’re looking for are always front and center.

Down Range Gear is going to be spread out over several different websites, each with a specific focus, playing to the strengths of the platform. We’re saving downrangegear.com for other purposes so it’s being used as a landing and redirect page in the interim. Downrangegear.net is the commercial hub. This WordPress blog will support the site with a focus on gear information and related features. We chose to establish a separate Tumblr account because that format lends itself as a dedicated gallery for custom, one-off projects. We’re still looking for the best place to load the massive photo archive. A few other, satellite sites will be specific for products that need to stand apart. Other social media is still out for the time being. Word of mouth has worked very well for Down Range Gear but it’s only effective if the products are good; the quality of the work needs to speak for itself.

Shopping At Down Range Gear.

The only items listed for sale on downrangegear.net are those built and ready to ship. While the standard is 24 hours, a majority of orders will be filled the same day. If it’s on the site, it’s in stock. If it’s in stock, it ships. The downside is that certain options (colors/patterns) are limited to what is on hand so if you’re wondering why the item you’re looking for only comes in the color(s) you don’t want, that’s why. Availability will improve as time goes on.

Orders can be customized on a case by case basis though the work may be subject to additional cost.

Down Range Gear is going to have a very specific color palette. With few exceptions we’re going to be focusing on coyote brown as a solid earth tone, black for government/agency customers and Multicam where appropriate. This will expand to include ranger green and foliage/gray but there won’t be any “ninja” options in the core product line.

Orders are diligently followed first with receipt confirmation and then verification of shipment with tracking information. The email messages are generated from the primary Down Range Gear Gmail account (downrangegear@gmail.com,) meaning that although they are pre-formatted for efficiency, they are sent and monitored by a real, live human being and not automated from a secondary account. That means that we receive and respond to replies from those messages, putting you in touch with someone who knows gear and has a vested interest in your experience. So if you need to talk to someone at any point in the order process, just reply directly to the email notification and we’ll be in touch promptly.

All shipping is via USPS unless otherwise specified. Shipping is a flat fee of $5 regardless of the size of the order and applies anywhere in the US to include APO/FPO orders. The only exceptions are for special shipping instructions from the customer or overseas orders.

Merchant services and payment processing at downrangegear.net go through PayPal. This can be controversial for some people and alternatives are being explored but all other considerations aside, PayPal is a very good starter platform for a small business because it’s easy to implement, straightforward to use, is reliable and well established. When the time is right and it makes sense to migrate to a different system, we will. Right now, we just want to design, build and sell gear with as little friction as possible.

Customer Service.

Competition and the rate of change in this industry can be grueling. A sense of humor helps but it does get ugly sometimes. While not above a little professional jealousy, as fellow consumers, we’re just as excited about the next great piece of gear as anybody. That’s the fun part. The business reality is that there are many paths to success: make a quality product, release breakthrough design concept, foster a new technology, build a fancy website, have a good business model, ride the wave of hype, get an endorsement from an industry personality, market like hell… the list goes on. At the end of the day, the customer makes the deciding and most important vote.

Among other things, we do what we do at Down Range Gear for the sheer joy of it. Everybody understands the satisfaction of putting out good work and that is reflected in the smallest details.

We honestly believe that customer problems are service opportunities as there is no better way to demonstrate real character than when things go wrong. We’re not going to hype the gear; there’s a power in the simplicity of understatement. When you’re proud of what you do, it can be difficult not to make a big deal of it but we strive to under promise and over deliver.

Our commitment doesn’t end after we’ve made a transaction. We sincerely believe that customer service starts in earnest after the order has shipped. We’re professionally invested in making sure the gear works and respect that there is no more honest feedback than from a paying customer who has skin in the game. Feedback drives the constant improvement that a business needs to stay fresh and innovative. You can’t fix the chink in your armor if you don’t know where it is, so when a customer takes the time to point out a problem and gives us the opportunity to make it right, that’s actually doing us a favor. We’re grateful when you do that.

We don’t do a lot of advertising and marketing, the time, money and effort generated by positive word of mouth from doing right by the customer more than makes up for it.

Custom Work, Parts And Materials.

Some really great ideas come from customers who have identified a need or bring a fresh perspective. The challenge with taking on obligations to do custom work are balancing them with the limited production capacity necessarily for developing the existing product line. That’s what we weigh every request against. We know there’s a constant need to customize gear and we’ll try to help whenever possible. As the business matures and the product pipeline finds it’s rhythm, the ability to do custom work will only improve.

Customers will notice that in addition to finished product in an establish product line, we’re also offering parts and materials for sale. These items are drawn from the same stock used to build finished product, essentially giving customers to access to a portion of the raw materials used to build gear.

The Future.

The apparent low barrier to entry has made for a crowded market. Anyone with a good idea, a sewing machine and a little time can hang out their shingle. That’s starting to change as technical materials and sophisticated fabrication methods change the industry but there’s still room for good ideas to stand out. Of course it takes more than that to run a business that will fulfill the needs of it’s customers and live up to it’s potential. The painful lesson learned is that business fundamentals still matter.

The big question is where does Down Range Gear fit in the wider industry? Is there still room for what we do and the way we do it? This is an existential matter! Are we making a difference? Does Down Range Gear stand out? These are questions we ask on a regular basis. You have to look externally at the wider industry and then internally at what you’re doing to find the answer.

At least part of the answer is that Down Range Gear doesn’t really play in market segments unless there’s a contribution to be made, something to add, or differentiate by feature or process. The excuse that there are only so many ways to build a certain design as a means to justify overlap in the industry really doesn’t hold up. It differentiates those who create from those who don’t among informed customers.

A certain amount of overlap and random confluence of design are inevitable but reworking an existing design just to stamp your brand on it is, if nothing else, a boring way to run a business. It might work if your primary goal is to chase dollars (not that there’s anything wrong with capitalism and giving customers choice is a good thing) but if that’s all there is, you’re just going through the motions, always one step behind. It’s not personally fulfilling and there’s no joy in the work. We can do better one design at a time by doing things that haven’t been done before or in ways they haven’t been done.

Up Next…

Down Range Gear on Photobucket

It takes a lot of photography to drive this blog.

It takes a lot of photography to drive this blog.

Though not in the same class as professional photography, the pictures are adequate to show the work in detail. And we really want customers to see everything. The pictures on the blog are high resolution and expand to full screen on white backgrounds to showcase the work. Click for the full page image and zoom in to see the fabric weave or a close up view of stitch work. Nothing says how much care or take pride in the work more clearly than the pictures.

We show everything. Buying decisions are made on those pictures and if a customer can’t get hands on a sample, the next best thing is a clean, detailed picture and useful descriptions. If a piece of work won’t stand up to that kind of scrutiny, it doesn’t ship. The attention to detail really drives the business.

In order to capture the half dozen or so images that illustrate the typical blog entry, literally hundreds of pictures may be required trying variations in light and angles. They all get processed through image filters to find the best way to present the product.

In the past, a select few have been loaded onto the blog with the remainder stowed on disc. The collection is extensive. It occurred to us that making these images available might be of interest to our customers (and, let’s face it -competitors.)

An organized Photobucket image library has been accumulating. As of this writing, it shows a relatively small selection but will grow with continual updates. The end result will be an expansive, detailed look at Down Range Gear’s portfolio.

Down Range Gear Photobucket Album.

Periodically checking in will not only show items currently offered, but from time to time, also reveal pending, unreleased projects. At lest two such items are in the album as of this writing. Whenever practical, blog entries will link to more extensive picture collections to give customers and readers an expanded view of the item.

Today @ Down Range Gear

Order 201109281442

The PALS Belt Platform is a short section of PALS (MOLLE) built on a solid backer designed for use on a belt and surfaced on both sides with nonslip material. It allows MOLLE (and compatible) pouch systems and accessory items to be properly woven onto a PALS grid allowing the user to take advantage of the full range of PALS compatible systems in a belt mounted role.

Usually built in a 2 column by 2 row grid, this piece was modified by customer request to accommodate 3 columns.

Tactical Holster Platform -Safariland

Some would say that Safariland 6004 tactical holsters define the product category. They are ubiquitous among serious, professional users.

Some would say that Safariland 6004 tactical holsters define the product category. They are ubiquitous among serious, professional users.

The original Drop Rig Belt Hanger was a drop-in upgrade for the 6004 hip extender assembly. It improved the function of the holster by combining and integrating some of the most sought after features. The result was a new system with enhancements incorporated into a unique design:

The original Drop Rig Belt Hanger was a drop-in upgrade for the 6004 hip extender assembly. It improved the function of the holster by combining and integrating some of the most sought after features. The result was a new system with enhancements incorporated into a unique design:

- Single point, push button latch for quick disconnect.

- Sized to mount the holster for high ride.

- Rock solid attachment.

- Compatible with both MOLLE and conventional belt systems.

- Swiveling buckle hardware allowing for a naturally ergonomic, arcing range of motion.

The original design has been continually improved since it’s release and is now highly refined. The core features are still there, but fine tuned after a lot of experience.

The original design has been continually improved since it’s release and is now highly refined. The core features are still there, but fine tuned after a lot of experience.

To mark the pending re-release, what follows is a top down look at the improved system that has been renamed “Tactical Holster Platform -Safariland.”

The heart of the system, giving it the features that set it apart from all others currently on the market is the National Molding/ Duraflex Swivi-Lockster buckle. The Swivi-Lockster is a unique latch system that allows for a single point, quick disconnect and is designed to pivot in a 120 arcing range of motion. There’s no other piece of hardware on the market with these features. It keeps the holster securely connected but easy to remove and moves on the leg with the wearer’s natural range of motion.

The heart of the system, giving it the features that set it apart from all others currently on the market is the National Molding/ Duraflex Swivi-Lockster buckle. The Swivi-Lockster is a unique latch system that allows for a single point, quick disconnect and is designed to pivot in a 120 arcing range of motion. There’s no other piece of hardware on the market with these features. It keeps the holster securely connected but easy to remove and moves on the leg with the wearer’s natural range of motion.

The upper half of the Tactical Holster Platform is the belt hanger. It supports the “female” end of the Swivi-Lockster buckle. Spaced widely apart for stability are two Tactical Tailor MALICE Clips who’s locked ends make for natural, secure belt loops. Passing the MALICE Clips through a series of PALS (MOLLE compatible) rows of webbing allows them to be properly woven into a PALS grid. Because this is a load bearing component, construction is especially robust in this critical area.

The upper half of the Tactical Holster Platform is the belt hanger. It supports the “female” end of the Swivi-Lockster buckle. Spaced widely apart for stability are two Tactical Tailor MALICE Clips who’s locked ends make for natural, secure belt loops. Passing the MALICE Clips through a series of PALS (MOLLE compatible) rows of webbing allows them to be properly woven into a PALS grid. Because this is a load bearing component, construction is especially robust in this critical area.

The bottom half of the Tactical Holster Platform directly supports the holster. It is a one-for-one, drop-in replacement for the existing OEM hip extender aligned with the Safariland three hole screw pattern. Like the part it replaces, it is supported on 2” scuba webbing but is not adjustable and only comes in one length: cut short to carry the holster as high as the hardware allows. At the top, a loop of 1.5” webbing attaches the Swivi-Lockster buckle and serves to secure the top portion of the shroud.

The bottom half of the Tactical Holster Platform directly supports the holster. It is a one-for-one, drop-in replacement for the existing OEM hip extender aligned with the Safariland three hole screw pattern. Like the part it replaces, it is supported on 2” scuba webbing but is not adjustable and only comes in one length: cut short to carry the holster as high as the hardware allows. At the top, a loop of 1.5” webbing attaches the Swivi-Lockster buckle and serves to secure the top portion of the shroud.

The best parts of the 6004 have been left alone. Parts that were merely functional have been upgraded to enhance performance of the system as a whole: quick detach, ergonomic range of motion, high ride, great belt and modular platform attachment options all in one well executed package. In this latest iteration, the Tactical Holster Platform has really hit it’s stride.

The Tactical Holster Platform will initially be available in coyote brown and black. And, for the first time, hardware will color match the material.

The Tactical Holster Platform will initially be available in coyote brown and black. And, for the first time, hardware will color match the material.

As good as it is, Tactical Holster Platform isn’t for everyone. The design excels with a very specific set of features for a narrow subset of professional users.

Down Range Gear’s Tactical Holster Platform integrates seamlessly with the Safariland tactical holster with a design that emphasizes function, adding versatility to the 6004 series tactical holsters.

The complete set of Tactical Holster Platform images is available on Down Range Gear’s Photobucket album.

Modular (EDC) Panel Insert

The Modular Panel Insert is the base component for Down Range Gear’s EDC (every day carry) system. Designed primarily as a drop-in organizer for backpacks, they can be made to order to fit various bags and cases in either horizontal or vertical orientations. The design is very basic but executed with exacting attention to detail: a rectangular panel (height and width made to order for the customer) with a Velcro surface that is configured into a PALS (MOLLE compatible) grid. These panels are incredibly versatile and can support equipment in a number of different ways. The PALS/Velcro surface runs top to bottom, edge to edge with no wasted space. The panel supports it’s weight with a removable, heavy duty, internal plastic frame sheet, allowing it to stand and maintain it’s shape. It’s simple but effective. Assembling each one to custom specifications is time consuming and labor intensive, thus expensive, but no corners are cut anywhere in fabrication.

The Modular Panel Insert can be enhanced with add-on features like the pull-out handle and custom designed, integral, elastic flat pockets. The pull out handle allows the user to extract the entire panel from the pack in order to quickly access the contents. Drop-in simplicity means that panels can be swapped between different packs or multiple panels can be configured for different purposes allowing the user to hot swap multiple load-outs for the same bag. Sewn-in, elastic flat pockets are lightweight, low profile and versatile organizers that can securely accommodate a variety of differently shaped and sized objects. They are a great alternative to add on pouch systems and can also be tailor made to fit the customer’s needs.

The Modular Panel Insert can be enhanced with add-on features like the pull-out handle and custom designed, integral, elastic flat pockets. The pull out handle allows the user to extract the entire panel from the pack in order to quickly access the contents. Drop-in simplicity means that panels can be swapped between different packs or multiple panels can be configured for different purposes allowing the user to hot swap multiple load-outs for the same bag. Sewn-in, elastic flat pockets are lightweight, low profile and versatile organizers that can securely accommodate a variety of differently shaped and sized objects. They are a great alternative to add on pouch systems and can also be tailor made to fit the customer’s needs.

Although outwardly simple, the attention to detail and customization comes at a premium. That said, the panels can be a significant upgrade to a pack system configured for the EDC role and are solidly built to last.

Today @ Down Range Gear

Order 201109010000: make a Tactical Tailor Mini-MAV work with a Mayflower Research & Consulting harness, upgrade the rig with Down Range Gear’s Enhanced Strap Replacement, Waist Strap and Side Straps.

Mating the Mini-MAV to the Mayflower harness was primarily a matter of achieving buckle compatibility. Familiar territory for Down Range Gear.

The real performance upgrade was the Enhanced Strap Replacement package which brings features like ergonomic front pull to adjust and the benefits of constant elastic tension to the conventional harness setup. Superior comfort is a natural byproduct of a harness system with straps that have an elastic core, which stretches and moves dynamically with the wearer rather than resist movement. The system just works and it’s just better than anything else currently on the market.

Raider Direct-To-Armor Panel.

Modern armor systems, whether comprehensive protective ensembles or high mobility plate carriers are heavy but inherently balanced and stable. This characteristic gives them structure to support a laden chest rig. Since armor is ubiquitous in military operations, there are a lot of advantages to running a chest rig directly attached without a harness.

We call this concept “Direct-To-Armor.” And you’re going to be seeing a whole lot more of it from Down Range Gear.

Chest rigs allow for the separation of load carriage from armor. There are many situations where armor is necessary but a fighting load is not. The chest rig also frees the user from layout and configuration limitations where the useful PALS (MOLLE) space is constrained by the size and shape of the armor system. Chest rigs keep the load in the user’s workspace.

A distinct advantage of the Direct-To-Armor approach is the quick disconnect feature. Configured properly, it functions and feels like a part of the armor system. On the surface, the two characteristics might seem contradictory, but Direct-To-Armor represents a new approach for users with a need to separate armor from load carriage yet run the two in an integrated manner.

After years of experience developing the Chest Rig/ Armor Interface Kit, which adapted third party, off the shelf chest rigs for armor attachment, the decision was made to take the lessons learned and build them into a chest rig from the ground up. Geared towards military users, the Raider Direct-To-Armor panel is the culmination of extensive experience in this area.

This latest iteration advances the design.

The Raider panel is designed to take maximum advantage of the armor system as a load bearing platform. It sacrifices standalone function to realize the benefits of armor integration, making the harness unnecessary.

The Raider panel is designed to take maximum advantage of the armor system as a load bearing platform. It sacrifices standalone function to realize the benefits of armor integration, making the harness unnecessary.

The attachment system is what makes it all work. The Raider panel supports Direct-To-Armor with four balanced points of attachment designed to clip in quickly.

Vertical attachment supports the load; the Raider panel utilizes two 1” ITW Nexus GhillieTex side release buckles for this. Latch (male end) buckles are sewn into the chest rig at two points. The panel tapers down from the buckles, angling off to the sides distributing the load evenly across the top. They clip into ITW QASM (female) buckles anchored onto PALS loops using QASM Vertical Connectors. This allows the vertical attachment points on the armor system to be positioned and fitted to the end user.

Vertical attachment supports the load; the Raider panel utilizes two 1” ITW Nexus GhillieTex side release buckles for this. Latch (male end) buckles are sewn into the chest rig at two points. The panel tapers down from the buckles, angling off to the sides distributing the load evenly across the top. They clip into ITW QASM (female) buckles anchored onto PALS loops using QASM Vertical Connectors. This allows the vertical attachment points on the armor system to be positioned and fitted to the end user.

Horizontal attachments stabilize the load, not taking on weight so much  as balancing the panel out and pulling it flat. On the Raider panel, this is done with PALS Shock Cord Anchors. Widely spaced grommets position the cord to pull evenly on the top and bottom edges of the panel. Shock cord is the preferred method because the constant, elastic tension requires no manual adjustment and is properly balanced every time. The cord tethers either an ITW G-hook or ITW GTSR buckle to the panel. G-hooks attach directly onto PALS webbing loops and are held in place under tension without the need for a additional hardware. This means that when the chest rig is not attached, it leaves no footprint. The ITW GTSR latch (male) buckle requires a compatible QASM buckle but provides a level of clip-in ease that can only be had with a side release buckle. The low profile QASM must necessarily remain on the armor system even when the chest rig is removed. Each attachment method has advantages and disadvantages. The Raider Direct-To-Armor panel will ship with both buckle systems along with spare cord and hardware to give the end user choice, and peace of mind.

as balancing the panel out and pulling it flat. On the Raider panel, this is done with PALS Shock Cord Anchors. Widely spaced grommets position the cord to pull evenly on the top and bottom edges of the panel. Shock cord is the preferred method because the constant, elastic tension requires no manual adjustment and is properly balanced every time. The cord tethers either an ITW G-hook or ITW GTSR buckle to the panel. G-hooks attach directly onto PALS webbing loops and are held in place under tension without the need for a additional hardware. This means that when the chest rig is not attached, it leaves no footprint. The ITW GTSR latch (male) buckle requires a compatible QASM buckle but provides a level of clip-in ease that can only be had with a side release buckle. The low profile QASM must necessarily remain on the armor system even when the chest rig is removed. Each attachment method has advantages and disadvantages. The Raider Direct-To-Armor panel will ship with both buckle systems along with spare cord and hardware to give the end user choice, and peace of mind.

The size and shape of the Raider panel were given a great deal of consideration. The primary concern is PALS space for pouch attachment. It’s a matter of how much and in what configuration. 3 rows (height) are a basic, minimal standard for most ammunition and accessory pouches and provide the user with the most versatility. The columns (width) were determined by the need to fit a footprint of three magazine pouches with two accessory pouches on either side.

The size and shape of the Raider panel were given a great deal of consideration. The primary concern is PALS space for pouch attachment. It’s a matter of how much and in what configuration. 3 rows (height) are a basic, minimal standard for most ammunition and accessory pouches and provide the user with the most versatility. The columns (width) were determined by the need to fit a footprint of three magazine pouches with two accessory pouches on either side.

The angled sides and undercut center also make for easier access to internal storage. The entire internal volume of the Raider panel is accessible with three pockets arranged symmetrically and accessed from the top center, left and right of the panel. The angled sides improve access to the side pockets. The undercut center also makes it easy to index the middle space. The interior pockets are subdivided internally to help with organization. Finally, the back of the panel has three, open top, flat pockets who’s size and layout correspond to the internal volume but are easier to get to.

The angled sides and undercut center also make for easier access to internal storage. The entire internal volume of the Raider panel is accessible with three pockets arranged symmetrically and accessed from the top center, left and right of the panel. The angled sides improve access to the side pockets. The undercut center also makes it easy to index the middle space. The interior pockets are subdivided internally to help with organization. Finally, the back of the panel has three, open top, flat pockets who’s size and layout correspond to the internal volume but are easier to get to.

All seams are sewn twice, with additional passes for critical, high stress areas.

This version of the Raider panel utilized a single layer of 1000D Cordura fabric, splitting the difference between lightweight and overbuilt “bomb proof.” Despite the interest in 500 weight fabric construction, there remains a lot to be said for the abrasion resistance of sturdy, proven 1000D fabric, though lightweight 500D variants will be made available.

Stand Down

Today @ Down Range Gear

Order 201108261321.

This job was familiar territory, an area in which Down Range Gear is associated: modify an off the shelf chest rig, adding Direct-To-Armor capability, retain standalone functionality and improve upon the basic components.

The chest rig was an Eagle Universal/ SKD Version. The customer wanted it modified to interface with a Mayflower Research and Consulting armor carrier. There is a large user base looking for ways to attach chest rigs to armor carriers not designed to go together. There’s more to it than adding straps and buckles in the right places. Additionally, the customer wanted to be able to continue using the chest rig as a standalone item with the original harness. These features aren’t mutually exclusive but imposing multiple requirements on a design that hasn’t been optimized for them inevitably leads to trade-offs.

The chest rig was an Eagle Universal/ SKD Version. The customer wanted it modified to interface with a Mayflower Research and Consulting armor carrier. There is a large user base looking for ways to attach chest rigs to armor carriers not designed to go together. There’s more to it than adding straps and buckles in the right places. Additionally, the customer wanted to be able to continue using the chest rig as a standalone item with the original harness. These features aren’t mutually exclusive but imposing multiple requirements on a design that hasn’t been optimized for them inevitably leads to trade-offs.

In it’s original configuration, the chest rig had two 1.5” buckles along the top of the panel. These needed to be switched out for 1” buckles and moved closer to center to align with compatible buckles on the Mayflower armor carrier. The customer was also concerned about how the narrower set of the new buckles would work when worn with the harness. A narrower attachment point means that the shoulder straps of the harness angle in differently. Multiple steps were necessary to satisfy all the requirements and make everything work together.

In it’s original configuration, the chest rig had two 1.5” buckles along the top of the panel. These needed to be switched out for 1” buckles and moved closer to center to align with compatible buckles on the Mayflower armor carrier. The customer was also concerned about how the narrower set of the new buckles would work when worn with the harness. A narrower attachment point means that the shoulder straps of the harness angle in differently. Multiple steps were necessary to satisfy all the requirements and make everything work together.

The original chest rig waist strap was a simple webbing and buckle combination run off the bottom corners of the panel. This is less than optimal in the Direct-To-Armor role because it leaves the top corners unsupported. The base chest rig is essentially a rectangle. Optimally, the sides need to pull evenly across the entire edge to properly balance the load. To address this concern, the edges of the panel were retrofitted with a 2” webbing tapered extension culminating in a 1” latch (male end) side release buckle. This entailed opening up the edges of the chest rig, dropping the new extension into the seam and sewing it up again. Care was taken to reinforce this critical stress point.

The original chest rig waist strap was a simple webbing and buckle combination run off the bottom corners of the panel. This is less than optimal in the Direct-To-Armor role because it leaves the top corners unsupported. The base chest rig is essentially a rectangle. Optimally, the sides need to pull evenly across the entire edge to properly balance the load. To address this concern, the edges of the panel were retrofitted with a 2” webbing tapered extension culminating in a 1” latch (male end) side release buckle. This entailed opening up the edges of the chest rig, dropping the new extension into the seam and sewing it up again. Care was taken to reinforce this critical stress point.

The Enhanced Strap Replacement, Waist Strap is a signature Down Range Gear design. It is a drop in replacement for conventional waist strap assemblies. The tubular webbing sheathed, shock cord core allows it to flex and maintains constant elastic tension. The webbing straps on either side are fed through ladderlocks, which are configured for an ergonomic, front pull to adjust. It’s a comfortable, user friendly, hard use upgrade that exceeds conventional strap systems.

The Enhanced Strap Replacement, Waist Strap is a signature Down Range Gear design. It is a drop in replacement for conventional waist strap assemblies. The tubular webbing sheathed, shock cord core allows it to flex and maintains constant elastic tension. The webbing straps on either side are fed through ladderlocks, which are configured for an ergonomic, front pull to adjust. It’s a comfortable, user friendly, hard use upgrade that exceeds conventional strap systems.

Today @ Down Range Gear

Sooner or later everyone acquires that piece of gear; the one item they can’t find the right pouch for. And it’s different for every user.

Sooner or later everyone acquires that piece of gear; the one item they can’t find the right pouch for. And it’s different for every user.

Having a customer bring a problem like this is invaluable because it identifies market niches. From a designer’s point of view, it’s also really fun to work on projects that aren’t a part of the scheduled production pipeline and a great learning opportunity.

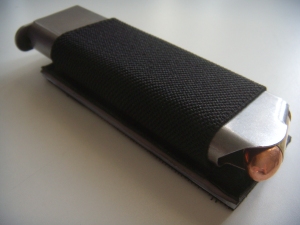

Case in point: this Surefire light pouch.

A light configured this way can’t be bought from Surefire; it’s been pieced together by the end user. Little wonder a pouch solution doesn’t exist. These were the requirements as communicated by the customer: securely holds light bezel up, sides of pouch extend to just under lamp assembly, removable/adjustable lid flap, secures with hook and loop, section of loop sewn onto the lid flap.

The pictures speak for themselves. It’s a minimalist pouch with very clean lines.

While the customer communicates what he wants, there’s usually room for the designer to exercise some creativity. Having someone who knows how to really build gear is a good starting point. Having someone with extensive end user experience is better.

Structure is everything in this pouch design and it shows in all the ways corners weren’t cut. This wasn’t a generic pouch. It was exactingly sized and cut to a very specific profile. The contour had to fit the light perfectly; too tight it’s worthless to the user and too loose, it’s an inefficient design with wasted space. The backing is doubled over 1.5″ webbing, the body is two layers of laminated 1000D Cordura with an HDPE plastic insert to ensure the pouch keeps it’s shape.

Structure is everything in this pouch design and it shows in all the ways corners weren’t cut. This wasn’t a generic pouch. It was exactingly sized and cut to a very specific profile. The contour had to fit the light perfectly; too tight it’s worthless to the user and too loose, it’s an inefficient design with wasted space. The backing is doubled over 1.5″ webbing, the body is two layers of laminated 1000D Cordura with an HDPE plastic insert to ensure the pouch keeps it’s shape.

A lot of pouch designs use pleated ends. That’s where the bottom of the pouch is folded and sewn down against the backing while the pouch billows out as it extends upwards.  It’s a relatively easy way to build a pouch but doesn’t necessarily make the most efficient use of available space. Depending on the size and shape of the contents, the item may never actually bottom out on a pleated pouch. That’s because the pouch gets progressively narrower the lower it goes. At some point, the width of the item won’t fit any deeper into the pouch and there is wasted space at the bottom. Down Range Gear doesn’t build pouches like that unless there is a specific reason. Creating a pouch with boxed corners can be both time consuming and more complicated to design. If a corner is properly boxed and the internal volume is a rectangle, all of the space and the entire footprint of the pouch is used. That’s a Down Range Gear design signature.

It’s a relatively easy way to build a pouch but doesn’t necessarily make the most efficient use of available space. Depending on the size and shape of the contents, the item may never actually bottom out on a pleated pouch. That’s because the pouch gets progressively narrower the lower it goes. At some point, the width of the item won’t fit any deeper into the pouch and there is wasted space at the bottom. Down Range Gear doesn’t build pouches like that unless there is a specific reason. Creating a pouch with boxed corners can be both time consuming and more complicated to design. If a corner is properly boxed and the internal volume is a rectangle, all of the space and the entire footprint of the pouch is used. That’s a Down Range Gear design signature.

This pouch was designed to be PALS (MOLLE) compatible with the use of Tactical Tailor MALICE Clips. This is the preferred method of attachment at Down Range Gear, even for belt pouches. Why? It allows the user to attach the pouch on multiple platforms. The MALICE Clip also makes an incredibly secure and durable plastic belt loop. That said, the MALICE Clip is not inherently stable on a belt without an adapter. Combined with an item like the MALICE Clip Belt Stabilizer or PALS Belt Platform,  both of which are built with either Velcro or high friction, nonslip liners, the pouch is superior in the belt mounted role to any purpose built belt loop design on the market today.

both of which are built with either Velcro or high friction, nonslip liners, the pouch is superior in the belt mounted role to any purpose built belt loop design on the market today.

We really love working on gear. Take a look at the pictures. Imagination precedes design made real with nylon and thread. We lavish a lot of time on the photography. The picture files are huge and detailed. Zoom in close and you’ll see the weave of the fabric and minutiae like obsessive attention to symmetry and stitch lines. Can you tell we’re having fun? Does it come through in the pictures? Building cool gear never gets old.

Drop Rig Belt Hanger Ships Free, While Supplies Last

There’s a small batch of Drop Rig Belt Hangers (Direct Mount, Safariland compatible, high ride) in coyote brown with black Swivi-Lockster buckles available. One of the changes instituted before the recent design update was to color match hardware. Down Range Gear is offering free shipping on the limited quantity of coyote brown system built with black buckles still in inventory. That’s a $35 flat fee, out the door, strictly limited to stock on hand. These are not available anywhere else in coyote brown and the next batch won’t come on line until mid October.

There’s a small batch of Drop Rig Belt Hangers (Direct Mount, Safariland compatible, high ride) in coyote brown with black Swivi-Lockster buckles available. One of the changes instituted before the recent design update was to color match hardware. Down Range Gear is offering free shipping on the limited quantity of coyote brown system built with black buckles still in inventory. That’s a $35 flat fee, out the door, strictly limited to stock on hand. These are not available anywhere else in coyote brown and the next batch won’t come on line until mid October.

To order, request a quote or verify availability, contact Down Range Gear via email at downrangegear@gmail.com

Today @ Down Range Gear

This entry is from a job a couple of months old. The requirement was to integrate a Camelbak hydration carrier directly to a P2Sys armor system yet still allow the hydration carrier to be used as a standalone pack. Familiar territory for Down Range Gear.

This entry is from a job a couple of months old. The requirement was to integrate a Camelbak hydration carrier directly to a P2Sys armor system yet still allow the hydration carrier to be used as a standalone pack. Familiar territory for Down Range Gear.

The P2Sys armor system secures over the wearer’s shoulders with a layered hook and loop closure. This turned out to be convenient for the necessary vertical attachment points. A compatible hook and loop strip was assembled to support a side release buckle latch (male end) Velcroed into the shoulder portion of the vest. Low profile ITW QASM buckles were also easily integrated onto the shoulder straps of the hydration carrier. These stay flat and out of the way when the Camelbak is worn without armor.

Ease of use, low profile and leaving the Camelbak as close to it’s original form as possible were key design considerations second only to adding functional armor integration.

Ease of use, low profile and leaving the Camelbak as close to it’s original form as possible were key design considerations second only to adding functional armor integration.

There were many easy options to accomplish horizontal attachment. Since the weight of the hydration system is largely borne on the vertical axis, the horizontal attachments serve more as stabilization than a load bearing mechanism. Shock cord was used to keep the hydration system under constant elastic tension against the vest. Tethered to ITW G-hooks (which attach directly onto PALS/MOLLE webbing,) they eliminate the need for a two piece buckle set. When not attached to the armor system, the shock cord pulls the G-hooks out of the way, tight against the sides of the hydration carrier.