Back in October 2011, when the last post was made on this blog, Down Range Gear was facing a fundamental small business problem. A lot of unique concepts were shown publicly without the business infrastructure to sell them. Among other things in this business, you live and die by your original, differentiating ideas. If you show your cards and don’t make an effort to play the game, you’re stupid. And the business suffered for it. Hence the year (+) long retrenchment.

Back in October 2011, when the last post was made on this blog, Down Range Gear was facing a fundamental small business problem. A lot of unique concepts were shown publicly without the business infrastructure to sell them. Among other things in this business, you live and die by your original, differentiating ideas. If you show your cards and don’t make an effort to play the game, you’re stupid. And the business suffered for it. Hence the year (+) long retrenchment.

Since this blog went on hiatus, a lot of things have changed. The wider industry of course never stands still. A number of concepts that first showed up on this blog years ago have gone mainstream. Despite the quiet outward appearance, Down Range Gear has maintained a very busy tempo behind the scenes. That’s what the rest of this post is about.

Down Range Gear has a new look, the best example of which is emerging at downrangegear.net, the new, standalone e-commerce site. If you haven’t found it yet, take a few seconds to have a look around. It’s a work in progress but the look and feel is starting to settle and the hard work of developing and listing product is well underway. It will steadily fill out in the weeks and months ahead.

Introducing downrangegear.net

Downrangegear.net was built on basic and dated software which will constrain functionality until it is migrated onto a more sophisticated platform. Despite this handicap, the design is deliberately simple. Functional issues aside, the key idea was to strip the site down to it’s most essential components in order to load quickly and then get out of the customer’s way. That means a clean design with big pictures, an intuitive layout that shows everything up front without the need for elaborate navigation with never more than 2 clicks to make a purchase.

If the site looks empty it’s because of the lack of extraneous content and clutter. Does the customer need to read a copy write notice? There are good legal reasons to have one but what does it have to do with buying gear? Shipping, warranty, contact information and a few links are all tucked in at the bottom and out of the way. You can find them if you need to but you probably didn’t jump on the site to read about that. The things you’re looking for are always front and center.

Down Range Gear is going to be spread out over several different websites, each with a specific focus, playing to the strengths of the platform. We’re saving downrangegear.com for other purposes so it’s being used as a landing and redirect page in the interim. Downrangegear.net is the commercial hub. This WordPress blog will support the site with a focus on gear information and related features. We chose to establish a separate Tumblr account because that format lends itself as a dedicated gallery for custom, one-off projects. We’re still looking for the best place to load the massive photo archive. A few other, satellite sites will be specific for products that need to stand apart. Other social media is still out for the time being. Word of mouth has worked very well for Down Range Gear but it’s only effective if the products are good; the quality of the work needs to speak for itself.

Shopping At Down Range Gear.

The only items listed for sale on downrangegear.net are those built and ready to ship. While the standard is 24 hours, a majority of orders will be filled the same day. If it’s on the site, it’s in stock. If it’s in stock, it ships. The downside is that certain options (colors/patterns) are limited to what is on hand so if you’re wondering why the item you’re looking for only comes in the color(s) you don’t want, that’s why. Availability will improve as time goes on.

Orders can be customized on a case by case basis though the work may be subject to additional cost.

Down Range Gear is going to have a very specific color palette. With few exceptions we’re going to be focusing on coyote brown as a solid earth tone, black for government/agency customers and Multicam where appropriate. This will expand to include ranger green and foliage/gray but there won’t be any “ninja” options in the core product line.

Orders are diligently followed first with receipt confirmation and then verification of shipment with tracking information. The email messages are generated from the primary Down Range Gear Gmail account (downrangegear@gmail.com,) meaning that although they are pre-formatted for efficiency, they are sent and monitored by a real, live human being and not automated from a secondary account. That means that we receive and respond to replies from those messages, putting you in touch with someone who knows gear and has a vested interest in your experience. So if you need to talk to someone at any point in the order process, just reply directly to the email notification and we’ll be in touch promptly.

All shipping is via USPS unless otherwise specified. Shipping is a flat fee of $5 regardless of the size of the order and applies anywhere in the US to include APO/FPO orders. The only exceptions are for special shipping instructions from the customer or overseas orders.

Merchant services and payment processing at downrangegear.net go through PayPal. This can be controversial for some people and alternatives are being explored but all other considerations aside, PayPal is a very good starter platform for a small business because it’s easy to implement, straightforward to use, is reliable and well established. When the time is right and it makes sense to migrate to a different system, we will. Right now, we just want to design, build and sell gear with as little friction as possible.

Customer Service.

Competition and the rate of change in this industry can be grueling. A sense of humor helps but it does get ugly sometimes. While not above a little professional jealousy, as fellow consumers, we’re just as excited about the next great piece of gear as anybody. That’s the fun part. The business reality is that there are many paths to success: make a quality product, release breakthrough design concept, foster a new technology, build a fancy website, have a good business model, ride the wave of hype, get an endorsement from an industry personality, market like hell… the list goes on. At the end of the day, the customer makes the deciding and most important vote.

Among other things, we do what we do at Down Range Gear for the sheer joy of it. Everybody understands the satisfaction of putting out good work and that is reflected in the smallest details.

We honestly believe that customer problems are service opportunities as there is no better way to demonstrate real character than when things go wrong. We’re not going to hype the gear; there’s a power in the simplicity of understatement. When you’re proud of what you do, it can be difficult not to make a big deal of it but we strive to under promise and over deliver.

Our commitment doesn’t end after we’ve made a transaction. We sincerely believe that customer service starts in earnest after the order has shipped. We’re professionally invested in making sure the gear works and respect that there is no more honest feedback than from a paying customer who has skin in the game. Feedback drives the constant improvement that a business needs to stay fresh and innovative. You can’t fix the chink in your armor if you don’t know where it is, so when a customer takes the time to point out a problem and gives us the opportunity to make it right, that’s actually doing us a favor. We’re grateful when you do that.

We don’t do a lot of advertising and marketing, the time, money and effort generated by positive word of mouth from doing right by the customer more than makes up for it.

Custom Work, Parts And Materials.

Some really great ideas come from customers who have identified a need or bring a fresh perspective. The challenge with taking on obligations to do custom work are balancing them with the limited production capacity necessarily for developing the existing product line. That’s what we weigh every request against. We know there’s a constant need to customize gear and we’ll try to help whenever possible. As the business matures and the product pipeline finds it’s rhythm, the ability to do custom work will only improve.

Customers will notice that in addition to finished product in an establish product line, we’re also offering parts and materials for sale. These items are drawn from the same stock used to build finished product, essentially giving customers to access to a portion of the raw materials used to build gear.

The Future.

The apparent low barrier to entry has made for a crowded market. Anyone with a good idea, a sewing machine and a little time can hang out their shingle. That’s starting to change as technical materials and sophisticated fabrication methods change the industry but there’s still room for good ideas to stand out. Of course it takes more than that to run a business that will fulfill the needs of it’s customers and live up to it’s potential. The painful lesson learned is that business fundamentals still matter.

The big question is where does Down Range Gear fit in the wider industry? Is there still room for what we do and the way we do it? This is an existential matter! Are we making a difference? Does Down Range Gear stand out? These are questions we ask on a regular basis. You have to look externally at the wider industry and then internally at what you’re doing to find the answer.

At least part of the answer is that Down Range Gear doesn’t really play in market segments unless there’s a contribution to be made, something to add, or differentiate by feature or process. The excuse that there are only so many ways to build a certain design as a means to justify overlap in the industry really doesn’t hold up. It differentiates those who create from those who don’t among informed customers.

A certain amount of overlap and random confluence of design are inevitable but reworking an existing design just to stamp your brand on it is, if nothing else, a boring way to run a business. It might work if your primary goal is to chase dollars (not that there’s anything wrong with capitalism and giving customers choice is a good thing) but if that’s all there is, you’re just going through the motions, always one step behind. It’s not personally fulfilling and there’s no joy in the work. We can do better one design at a time by doing things that haven’t been done before or in ways they haven’t been done.

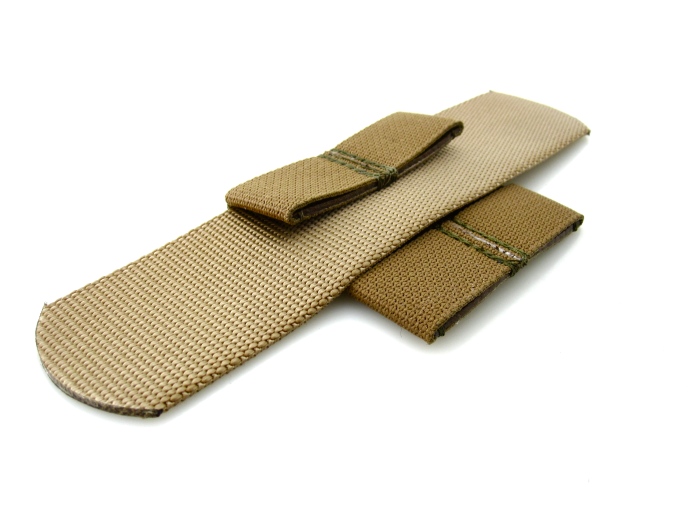

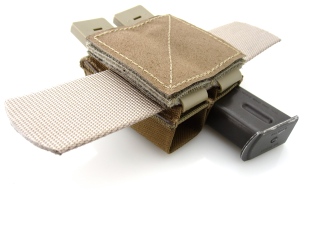

The PALS Belt Platform is designed to be stable on belts both with and without Velcro liners. An opposing hook and loop surface is built in for contact with the underside of compatible belts. It works well with two tier, inner/outer duty belt sets. For belts without Velcro, removable, non-slip patches can be affixed to both sides to increase friction and minimize shifting.

The PALS Belt Platform is designed to be stable on belts both with and without Velcro liners. An opposing hook and loop surface is built in for contact with the underside of compatible belts. It works well with two tier, inner/outer duty belt sets. For belts without Velcro, removable, non-slip patches can be affixed to both sides to increase friction and minimize shifting. Some of the most innovative and original pouch designs on the market today are built for modular attachment. They can now be run as low profile, dedicated belt pouches. The PALS Belt Platforms joins the MALICE Clip Belt Stabilizer and CDH-Tac’s Lowride Panel in Down Range Gear’s line of adapters.

Some of the most innovative and original pouch designs on the market today are built for modular attachment. They can now be run as low profile, dedicated belt pouches. The PALS Belt Platforms joins the MALICE Clip Belt Stabilizer and CDH-Tac’s Lowride Panel in Down Range Gear’s line of adapters.